Mist Collection

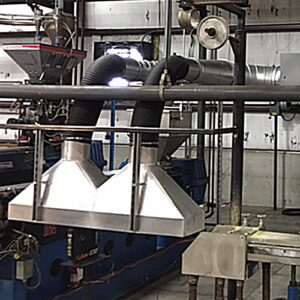

Industrial mist collection can be accomplished with several types of equipment. Knowing the application and process will help narrow down the best solution. There are several options and configurations involved in the design of a system, and come in floor or wall mount systems.

Mechanical Mist Separators (filter Media)

Mechanical Mist Separators are designed to separate emulsion nebulae formed during machining. The principle of separating oil droplets from the air is mechanical.

Mechanical Mist collection uses media technology to capture the oil or water mist or thermally generated smoke. Normally there are several stages of filtration to extend filter life. Many times, the final filters with be HEPA. There are filters designed for clean oil or water mist and also filters that are designed for mist that has dust or dirt. Mist collectors are most commonly used in metal cutting and machining applications.

- Typical applications. collect oil mist created by mechanical vacuum pumps, compressor pumps, gears, transmissions, reciprocating engines, turbines, etc.

Electrostatic Mist Separators (ESP)

ESPs are filtration devices that removes fine particles, like dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit.

Electrostatic Precipitators used a series of electrically charged rods and plates. When the contaminated air passes by the rods it is given a positive electrical charge. Then, as the air passes though these negatively charges plates, the contaminates are attracted to the plates and out of the gas stream. The collected contaminates can be recycled or disposed of. Many times there is a media pre-filter to help reduce maintenance and cleaning.

ESP collectors are most commonly used in metal cutting and machining applications. They can also be used on welding certain types of welding applications.